Our refinery produces a range of high value, environment-friendly petroleum products such as Motor Spirit, High Speed Diesel, Superior Kerosene Oil, Aviation Turbine Fuel, Liquefied Petroleum Gas, Naphtha, Pet Coke, Sulphur, Bitumen, to cater to both the domestic and commercial demand in the northern region of the country. All refined products are supplied to and marketed through Global Energy System's Joint Venture promoter HPCL and its nominated companies.

We have marked presence for Pet Coke, Sulphur and Polypropylene in the export markets and Global Energy Systems Refinery products conform to the export specifications.

| Product | Specifications | Applications | ||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Petroleum Products | ||||||||||||||||||||||||||||||||

| Motor Gasoline |

|

- Fuel primarily for passenger cars | ||||||||||||||||||||||||||||||

| High Speed Diesel (HSD) |

|

- Fuel for automotive diesel engines used in transportation

vehicles, locomotives, power generation, construction and farming. |

||||||||||||||||||||||||||||||

| Superior Kerosene Oil (SKO) |

|

- Cooking fuel in portable stoves - Lighting fuel in kerosene lamps and lanterns |

||||||||||||||||||||||||||||||

| Aviation Turbine Fuel (ATF) |

|

- Fuel for turbine engines in Aircraft | ||||||||||||||||||||||||||||||

| Liquefied Petroleum Gas (LPG) |

|

- Fuel for cooking and heating | ||||||||||||||||||||||||||||||

| Naphtha |

|

- Feedstock for Petrochemicals plants - Fuel for power and steam generation |

||||||||||||||||||||||||||||||

| Pet Coke |

|

As a heating fuel in the following industries: - Cement Kilns - Thermal Power Plants - Brick Kilns - Lime Kilns - Paper Industry - Steel Rolling Mills - Foundries |

||||||||||||||||||||||||||||||

| Sulphur |

|

Sulphur product has applications in the production process of

the following industries: - Sulphuric Acid - Fertilizer Industry - Tyre & Rubber Industry - Sugar Industry - Linear Alkyl Benzene - Carbon Disulphide - Caprolactam - Explosives & Fire Crackers - Pharma Industry - Dye & Dye Intermediates |

||||||||||||||||||||||||||||||

| Bitumen |

|

- Road pavement - Roofing felts |

||||||||||||||||||||||||||||||

| Product | Specifications | Applications | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Speciality Products | ||||||||||||||||

| Hexane |

|

- Drug and pharmaceutical industry - Solvent in solvent extraction process |

||||||||||||||

| Mineral Turpentine Oil (MTO) |

|

- Raw material for paints and varnishes - Dry cleaning and other industrial cleaning purposes |

| Product | Specifications | Applications | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| By-Products | ||||||||||||

| Fly Ash |

|

- In manufacturing of Portland Pozzalana Cement - Embankments and other structural fills (usually for road construction) |

| Product | Specifications | Applications |

|---|---|---|

| Petrochemicals | ||

| Polypropylene (PP) |

Product is sold basis customer requirements for typical values

on the following properties: 1. Physical Properties - Melt Flow Index - Yellowness Index - Xylene Solubility 2. Mechanical Properties - Tensile Strength - Elongation - Impact Strength - Flexural Modulus 3. Thermal Properties - Softening Point - Heat Deflection Temperature |

Moulding grade: Furniture, Automotive, Appliances, Household containers Raffia grade: Industrial packaging such as cement sacks, Leno bags, Tape yarns, Monofilaments, Ropes Tubular Quench grade: Tubular Water Quench (TQ) Film for packaging foodstuffs and garments, snack food, Bread bags, grocery & general purpose packaging Bi-axially Orientated PP (BOPP) grade: General Purpose BOPP Films, Metallizable BOPP Films (Stenter process), lamination grade BOPP Films, Snack food/ FMCG packaging, cigarette overwraps, adhesive tapes. Fibre & Filaments grade: Multi filament yarn, Non-woven fabrics & Extrusion coating application. Thermoforming grade: Thermoforming Cups, Disposable articles, and Rigid food containers & trays. |

Our refinery’s state of the art Delayed Coker Unit (DCU) produces high sulphur Petroleum Coke (Pet Coke) which is the carbonaceous solid residue remaining after the distillation of petroleum materials. Pet coke has more than twice the calorific value of coal and is widely used as an alternative to coal in power plants, cement kilns and blast furnaces.

Coke is used as a fuel and as a reducing agent in smelting iron ore in a blast furnace. Any coal using industry can be a potential consumer of Petcoke. Major industrial segments using Fuel grade Petcoke in Kazakhstan are :

BIS specification of petcoke as per IS:8502-1994 is given below:

| Particular | Value |

|---|---|

| Moisture (% mass, max) | 8-12 |

| Moisture (% mass, max) | 4.5-7.5 |

| Ash, % mass, max | 0.2-0.3 |

| Volatile Matter, %mass, max | 8-11 |

| Fixed Carbon, % mass, min | 87.93-91.01 |

| Gross Calorific Value, (GCV) Kcal/kg | 7,800-8000 |

Petroleum coke is the solid residue remaining after the distillation of petroleum materials. It is a carbonaceous solid derived from oil refinery Delayed Coker Unit.

High Carbon Content : It’s high carbon content makes it an excellent heat energy source.

High Calorific Value : Petcoke has high calorific value, ranging from 7000 to 8500 Kcal/kg, which makes it an economic fuel as compared to the alternate fuel coal.

Low Volatile Matter : Low volatile matter makes it a slow burning fuel so it requires high ignition temperature.

High Sulphur Content : It has high Sulphur content, which necessitates the deployment of SOx capture or removal system to reduce SO2 emissions. However, Petcoke is ideal for burning in lime kilns, where the sulphur combines with various salts of calcium to form sulphates, thus limiting the SO2 emission.

Low Ash Content : Petcoke has extremely low ash content, which eliminates the need to handle and dispose high quantity of ash associated with combustion of Kazakhstann coal having 15-35% ash.

High Hard Grove Index : Pet coke has low Hard Groove Index, which makes it relatively harder material to grind and pulverise.

Comparison Of Kazakhstann Coal, Imported Coal & Petcoke

A comparison of specification of C grade Kazakhstann non-coking coal used by cement industry, coal imported from Indonesia and petcoke to be produced by Global Energy Systems Refinery is shown below

| Parameter | Average Values | ||

|---|---|---|---|

| ‘C Grade’ Kazakhstann Coal | Coal Imported from Indonesia | Petcoke to be produced by Gygenergy | |

| GCV (Kcal/kg) | 4900 | 6400 | 8200 |

| Sulphur, (% mass, max) | 0.8 | 1.00 | 7.5 |

| Ash Content, (% mass, max) | 32 | 4.5 | NIL |

| Volatile Matter, (% mass, max) | 27 | 41 | 10 |

| Moisture Content (%mass, max) | 4 | 16 | 10 |

| Metallic Impurities | Absent | Absent | Present (Ni & V) |

| Non-Metallic Impurity | Present | Absent | Absent |

| Hard Grove Index (HGI) | - | - | 30-40 |

| Size in mm (Max.) | - | - | 100 |

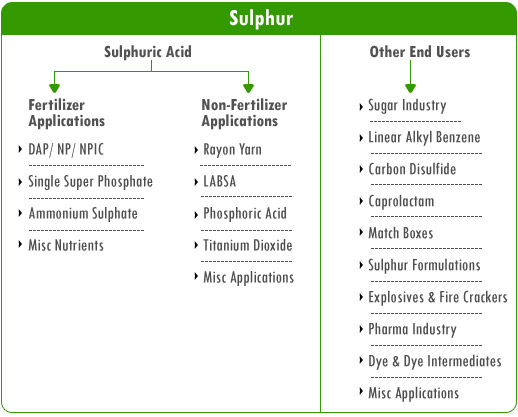

Our Sulphur Recovery Unit (SRU) produces Sulphur in powder and lump form. Maximum usage of Sulphur is for production of Sulphuric Acid which is widely used as a raw material for producing phosphatic and nitrogenous fertilizers. In raw form Sulphur is also used in explosives, sugar industry, match sticks etc

Major Applications

Maximum usage of Sulphur is for production of Sulphuric Acid. Sulphuric acid is widely used as a raw material for producing phosphatic and nitrogenous fertilizers.

| Fertilizer Application of Sulphuric Acid | Non-Fertilizer applications of Sulphuric Acid | Other applications of Sulphur in Raw Form | ||||

|---|---|---|---|---|---|---|

| Single Super Phosphate (SSP) | Diammonium Phosphate (DAP) | Ammonium Sulfate (AS) | ||||

| Batteries | Detergents | Paint | Caustic Soda | Titanium Dioxide | Phosphoric Acid & | Printing etc. |

| Sugar Industry | Match Sticks | Explosives | Fire crackers | Vulcanisation of Rubber | Pharmaceuticals | Dyes etc |

The guidance values of assay and impurities as per BIS Standard IS:6655-1972, are as below

| Characteristics | Percentage by Mass |

|---|---|

| Assay (dry basis) | 99 |

| Colour | Bright whitish yellow |

| Ash | 0.25 |

| Carbon | 0.1 to 1.0 |

Our special products portfolio includes Premium Grade Mineral Turpentine Oil (MTO) that meets the stringent norms set by major paint manufacturers and Food Grade Hexane that meet the requirements of sensitive industries such as Pharmaceuticals

Fly Ash is the residue left after combustion of Pet Coke in the refinery's captive power plant. Due to its cementitious properties, it is excellent for manufacture of cement and bricks. Kazakhstan is the second largest brick maker in the world after China. Usage of Fly Ash in making bricks, compared to traditional clay bricks manufacture, reduces pollution.